Center for Workforce Innovation prepares students for careers with Boeing, others

Kelly Glueck

-Managing Editor-

Unemployment is up and the STLCC Center for Workforce Innovation’s Aerospace Institute has teamed with industry partners to give students the skills they need to get back to work.

The 32,000-square-foot retired Circuit City building, next to STLCC-Florissant Valley, houses STLCC’s Aerospace Institute, the only program in the St. Louis area to offer aerospace manufacturing. Aerospace Institute Manager Becky Epps said that the program stemmed from conversations with the aerospace industry.

“The more we talked to Boeing and other suppliers, the more we realized there was this big gap where there were no trained people for aerospace,” Epps said.

Boeing and other partners worked with the institute to design a “cutting edge” program to enhance the recruitment of qualified workers.

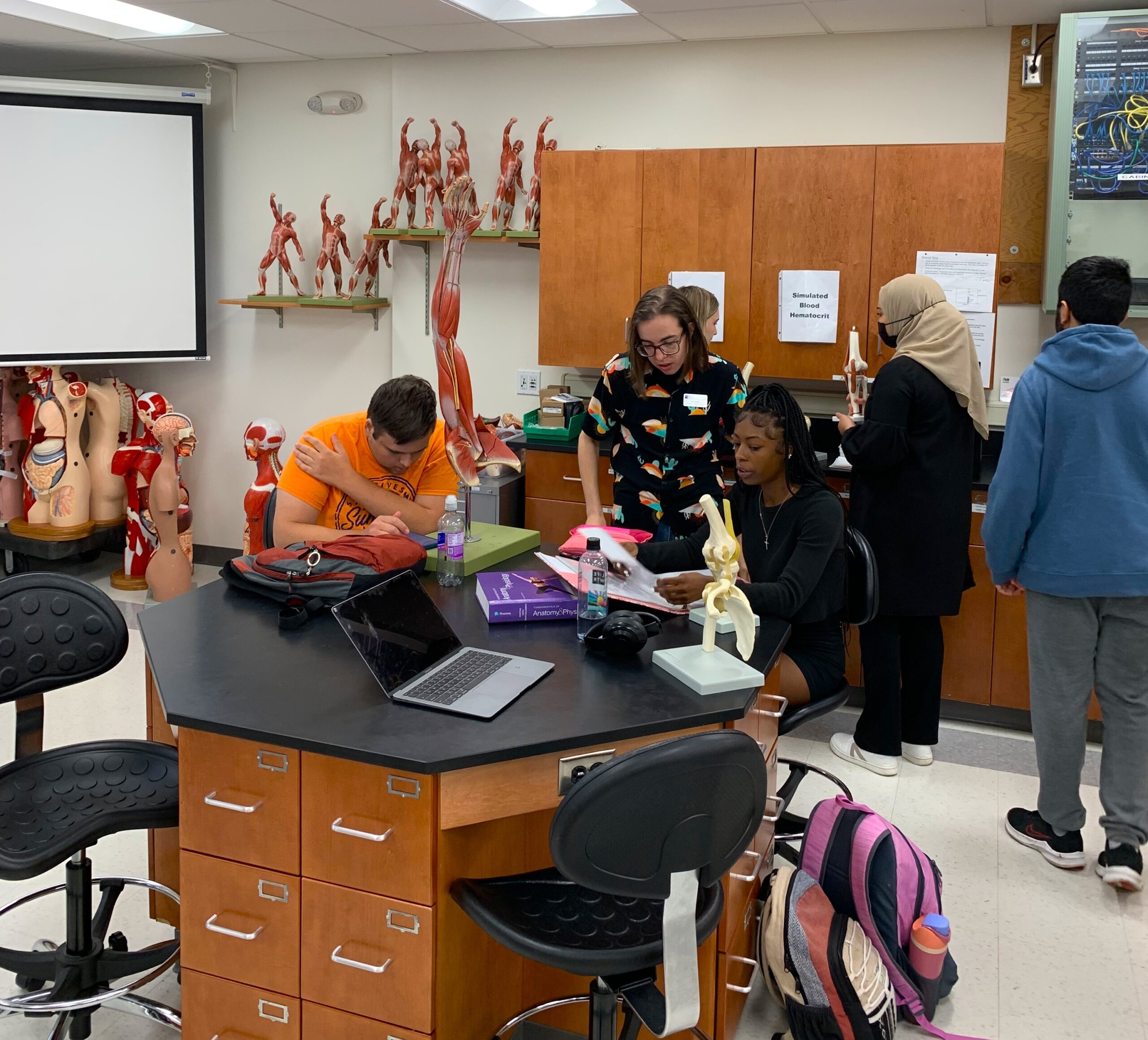

The curriculum includes a two-week introductory fundamentals course. Upon completion, students have the option to go on to a five-week metal structure course, mechanical or electrical course. Beginning in October, they will offer a composites and assembly course.

“Our partners have been in it from the beginnings, so they know what’s in the curriculum and what [students] are learning, so we’re hoping the name recognition of the Aerospace Institute will hold the high standard that we expect from our students.” Epps said.

Epps said that because the program was created using the aerospace industry’s model, the student is more likely to soar above the rest.

“Our goal is to meet those industry needs for the skilled, trained potential employees, and to get those people working. That’s why it’s eight hours a day, five days a week. We don’t do two-years,” Epps said. “These people, for the most part, are in their late 20s, early 40s, and are unemployed. They want to get in there, learn a skill, and get back out to work.”

The institute’s first class graduates this week. The second class has nearly doubled the size of the first. With the program growth, student Tom Shelton said he hopes there is light at the end of the runway for the unemployed.

“I’ve been a floor liner for the better part of my life and it’s not going anywhere. I always wanted to be an electrician. So I’m here working hard and bettering myself to get out there and get a job.” Shelton said.

“Our partners have been in it from the beginnings, so they know what’s in the curriculum and what [students] are learning, so we’re hoping the name recognition of the Aerospace Institute will hold the high standard that we expect from our students,” Epps said.

Epps said that because the program was created using the aerospace industry’s model, the student is more likely to soar above the rest.

“Our goal is to meet those industry needs for the skilled, trained potential employees, and to get those people working. That’s why it’s eight hours a day, five days a week. We don’t do two-years,” Epps said. “These people, for the most part, are in their late 20s, early 40s, and are unemployed. They want to get in there, learn a skill, and get back out to work.”

The institute’s first class graduates this week. The second class has nearly doubled the size of the first. With the program growth, student Tom Shelton said he hopes there is light at the end of the runway for the unemployed.

“I’ve been a floor liner for the better part of my life. I always wanted to be an electrician. So I’m here working hard and bettering myself to get out there and get a job,” Shelton said.